Tesla's accident repair standards hinge on digital torque specs, ensuring structural integrity and maintaining brand reputation for safety through meticulous paint repair and dent removal. Adherence to strict guidelines by specialized body shops is vital for enhancing Tesla owner safety on the road.

Tesla, a pioneer in electric vehicle (EV) technology, sets stringent safety standards that extend beyond conventional vehicles. When it comes to Tesla accident repair, adhering to Digital Torque Specs is paramount. This article delves into understanding Tesla’s rigorous safety requirements and explains why digital torque specifications are the cornerstone of accurate repairs, ensuring optimal safety and performance for these innovative electric cars. By exploring these key aspects, we highlight the importance of specialized knowledge in Tesla accident repair.

- Understanding Tesla's Strict Safety Standards

- Digital Torque Specs: The Core Requirement

- Ensuring Accurate Repair for Optimal Safety

Understanding Tesla's Strict Safety Standards

Tesla, a pioneering electric vehicle manufacturer, is renowned for its cutting-edge technology and stringent safety standards. When it comes to Tesla accident repair, compliance with digital torque specifications is just one aspect of their rigorous guidelines. The company’s commitment to safety ensures that every component, from battery systems to the vehicle’s frame, undergoes meticulous testing and certification.

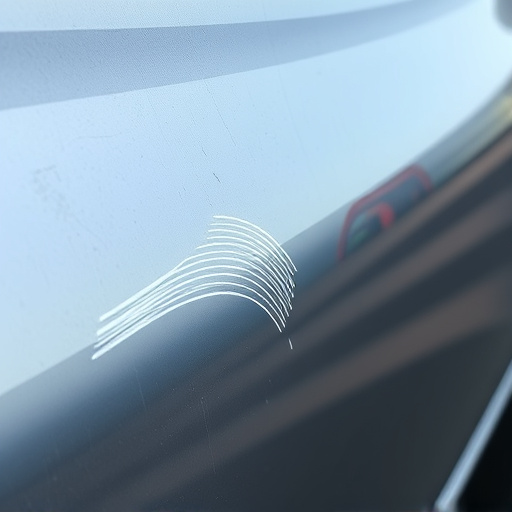

This focus on precision extends to repairs, particularly in specialized areas like vehicle paint repair and car dent removal. Tesla’s strict standards require repair shops to adhere to digital torque spec compliance during any mechanical work. This ensures not only the structural integrity of the vehicle but also maintains the brand’s reputation for innovative and safe automotive design.

Digital Torque Specs: The Core Requirement

In the realm of Tesla accident repair standards, Digital Torque Specs stand as a cornerstone requirement. These digital specifications are pivotal for ensuring that vehicle paint repair and overall vehicle body shop operations align with Tesla’s stringent quality control measures. Every detail, from the precision of mechanical adjustments to the meticulousness in auto collision center work, must comply with these specs.

Digital Torque Specs govern various aspects of the repair process, including the torque applied during bolting and tightening procedures. This ensures that every component is secured properly and safely, preventing any future issues or compromises in structural integrity. For a vehicle body shop looking to meet Tesla’s high standards, adhering to these digital specifications is not just recommended—it’s crucial for maintaining customer satisfaction and ensuring the safety of every restored vehicle.

Ensuring Accurate Repair for Optimal Safety

Maintaining accurate repair standards is paramount when it comes to Tesla vehicles, ensuring both optimal performance and safety on the road. With their advanced technology and innovative design, Tesla cars require precise handling during the accident repair process. Auto body services specializing in Tesla repairs must adhere to strict guidelines to meet these high standards.

Precision is key when dealing with digital torque specifications, as even minor deviations can impact the vehicle’s structural integrity. Skilled technicians utilize specialized tools and knowledge to accurately assess and correct damage, especially after incidents like hail damage repair. By staying up-to-date with Tesla’s latest repair guidelines, auto body shops can guarantee that every repair meets or exceeds vehicle body repair industry best practices, ultimately contributing to a safer driving experience for Tesla owners.

Tesla’s commitment to safety is evident through its stringent accident repair standards, which mandate digital torque spec compliance. By adhering to these precise guidelines, repair centers ensure that Tesla vehicles return to their optimal state of safety and performance. This advanced approach to automotive repairs sets a new benchmark in the industry, emphasizing the importance of technological precision for passenger protection.