Proper panel bonding techniques are crucial for Tesla's stringent accident repair standards, ensuring structural integrity, water resistance, and long-term corrosion prevention while maintaining vehicle safety, quality, and distinctive design, preserving car value and performance.

Tesla vehicles, known for their innovative technology, come with rigorous accident repair standards. When repairing a Tesla after an accident, adhering to proper panel bonding techniques is paramount. This article delves into understanding Tesla’s stringent accident repair standards and highlights the crucial role of expert panel bonding. By ensuring safety and quality through adherence to these standards, repair shops can restore Teslas to their original state, maintaining both performance and aesthetics.

- Understanding Tesla Accident Repair Standards

- The Role of Proper Panel Bonding Techniques

- Ensuring Safety and Quality through Adherence to Standards

Understanding Tesla Accident Repair Standards

When it comes to Tesla accident repair standards, understanding the specific requirements is paramount. Tesla vehicles are known for their advanced technology and innovative design, which means their repair process demands a higher level of precision and expertise. The brand sets rigorous standards to ensure that any repairs maintain the vehicle’s original quality and performance.

These standards cover various aspects, including panel bonding techniques for car bodywork. Proper bonding is crucial in ensuring structural integrity and the aesthetic appeal of the vehicle. A skilled vehicle body shop specializing in Tesla models should be adept at using advanced adhesives and sealing agents to achieve seamless fusion between panels. This not only guarantees the safety of the occupants but also preserves the vehicle’s value and its distinctive design elements, making it a critical consideration for any car bodywork services.

The Role of Proper Panel Bonding Techniques

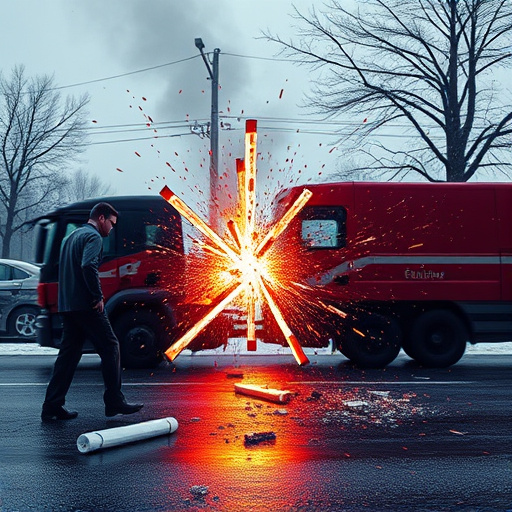

Proper panel bonding techniques play a pivotal role in adhering to Tesla accident repair standards. When a vehicle undergoes a collision or accident, ensuring seamless and durable repairs is paramount. Skilled technicians employ advanced methods to reattach and realign damaged panels, maintaining the structural integrity of the car’s body. This meticulous process involves precise application of adhesives and sealants, which not only hold the panels together but also prevent water intrusion and corrosion over time.

Adhering to these techniques is crucial for a car body shop aiming to provide top-notch collision repair services. Effective panel bonding ensures that the repaired vehicle not only looks like new but also performs optimally in terms of safety and durability. By utilizing modern tools and adhering to Tesla’s specific guidelines, qualified mechanics can restore vehicles to their pre-accident condition, giving them a second life on the road.

Ensuring Safety and Quality through Adherence to Standards

Tesla accident repair standards are a cornerstone of ensuring both safety and quality when it comes to restoring vehicles to their pre-accident condition. Adhering to these stringent guidelines is paramount for auto repair services aiming to deliver top-notch results, especially in cases of significant damage, such as vehicle bodywork with visible scars or scratches repair. These standards mandate precise panel bonding techniques that go beyond mere aesthetics; they reinforce structural integrity, preventing future safety hazards.

Proper panel bonding involves meticulous preparation, including surface cleaning and decontamination, to guarantee a durable bond between the repaired sections and the original vehicle bodywork. This meticulous approach is crucial in maintaining the overall quality and longevity of auto repair services, ensuring that every Tesla leaves the workshop as if it were brand new – safe, reliable, and ready to navigate the roads with confidence.

In conclusion, adhering to stringent Tesla accident repair standards is paramount for ensuring vehicle safety, structural integrity, and long-term performance. Proper panel bonding techniques play a crucial role in meeting these standards, as they guarantee seamless repairs that mimic the original construction. By prioritizing these methods, repair shops can deliver high-quality work that not only satisfies Tesla’s rigorous requirements but also protects the value and reliability of their vehicles for years to come.